Home Wearables HFM Mills Facebook

Heritage Farm 1923 Loom

Huntington, WV

by Cyndi Bolt

PREPARE OLD WARP FOR TYING ON -

The ends of the old warp are left threaded through

the heddles (wires with eyes on the moveable harnesses)

and the reed (metal piece with slots)

About 16 to 20 inches are needed to tie on to the new warp

Tie on two vertical support sticks (lary sticks - not shown)

from breast beam to the edges of the reed

Place the velcro covered stick on them and tie it down

OLD WARP TIED DOWN

Comb a section of old warp ends, raise the front harness,separate yarns into

odd threads (front harness) and

even threads (back harness)

Place old warp ends on velcro stick:

front harness threads to the left and back harness threads to the right

Now each thread in the threading sequence can be picked up to tie on to the new warp

NEW WARP TIED DOWN

Tie first warp chain to breast beam, on the right side

Tie the cross bar (piece of wood with the two tinker toys stick in it) to the breast beam

Put the weavers cross in the warp on the cross bar

Untie ends and trim evenly

Tie the cut ends down

You need the chain stable to pull each thread out of the cross

There are two threads in each dent (slot) of the reed

Separating the odd thread from the even threads lets you choose which thread is next in threaded sequence

Pick up the first thread of the old chain

Pick up the first thread on the cross bar

Tie the two threads together with an overhand knot, lay to the right side

Tie the rest of the warp on the same way

Repeat for the rest of the chains

A finished tied-on chain

BEAMING

Straighten the chains over the breast beam

Add weights (spring clamps with about 6 oz metal elbow pipe fittings)

Begin cranking on the warp

Straighten any tangled threads as you go

When weights come up to the breast beam, unchain some warp

and reattach the weights near floor level

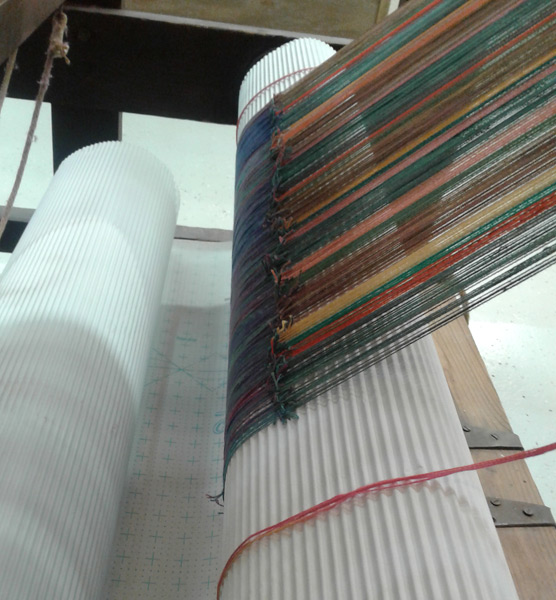

Wind corrigated paper (or other heavy paper) into the warp on the warp beam

(at the back of the loom) to keep threads even

Every few yards beamed, give each chain a hard pull to work excess slack out of the warp

TIE ON TO CLOTH BEAM ROD AND BEGIN WEAVING

When there are about 20 inches of the warp left unwound in front of the reed,

untie the ends of the warp and tie them to the cloth beam apron rod

Tie from the center outward

Tighten the warp to a moderate tension on the finished warp

Begin weaving

LOOM HISTORY

I was given this loom by a

lady who worked at Merrill-Lynch in Huntington, WV. She said she wanted to clear out her

basement. As far as I can remember, she

may have said her grandfather would use the loom for some rug weaving, when he

needed new rugs. I canít recall if he

was the maker or not.

The maker made the loom with materials he had in hand, in 1923. The loom is made with mortise and tenion joints, so you can take it apart and move or store it. The warp and cloth beams are rough logs. Door hinges to swing the beater and treadles. UNIQUE to this loom: a delicate bicycle sprocket as the back beam brake. Hand shaped metal pieces. The only pieces purchased are the reed and the harnesses.

Cyndi Bolt- - -

© Cyndi Bolt Designs

Website Design by Cyndi Bolt

cyndi@cyndibolt.com

304-849-4341

- - -

Mills Family Cemetery

Mills Family Cemetery and Historic Images